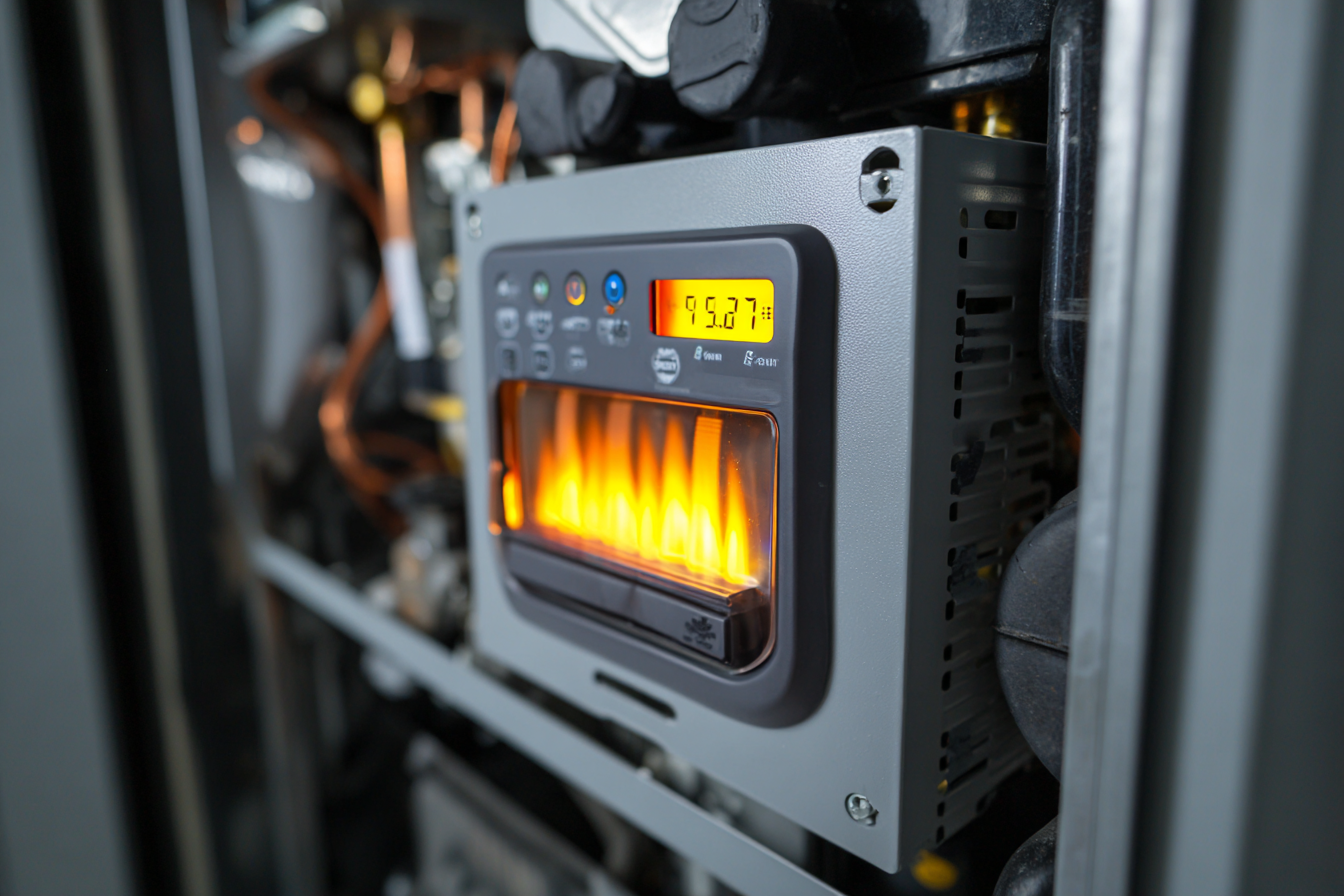

When a gas furnace underperforms, it can disrupt equipment uptime, delay production schedules, and increase maintenance downtime. Issues like uneven heating or unexpected breakdowns also drive up energy costs if left unresolved. With unplanned downtime costing industrial businesses around $250,000 per hour, even a single furnace failure can quickly become a costly operational issue.

You need a heating system that delivers consistent performance and minimizes interruptions. Understanding how long your gas furnace should last and recognizing early signs of wear can help you plan ahead. This approach helps maintain lead time stability, reduces emergency repair downtime, and protects operational efficiency.

In this blog, we’ll explore the average lifespan of gas furnaces, signs that it’s time for something new, and practical ways to keep your system running as long as possible.

Key Takeaways:

Gas furnace lifespan typically ranges between 15 and 25 years, influenced by furnace type, installation quality, usage patterns, and ongoing maintenance.

Replacement becomes necessary when issues such as frequent repairs, uneven heating, rising energy consumption, short-cycling, or safety warning signs begin to appear together.

Timing furnace replacement during spring, summer, or early fall helps reduce operational disruption and avoids emergency breakdowns during peak heating seasons.

Proper maintenance, early system evaluation, and informed replacement planning help maintain consistent heating performance and reduce unexpected downtime.

Average Lifespan of a Gas Furnace

Knowing the expected lifespan of your gas furnace helps plan for maintenance, budgeting, and system replacement. The type and design of your furnace influence how long it can reliably operate, impacting equipment uptime, repair costs, and overall operational continuity.

Understanding these differences helps you make better decisions and reduces unexpected downtime.

How Lifespan Varies by Furnace Type?

Not all gas furnaces are built the same way. The type of furnace you choose can affect how long it lasts, as well as its performance and energy consumption.

Standard Efficiency Furnaces: Typically have a lifespan of 15–20 years. You need to monitor these furnaces consistently to prevent breakdowns that disrupt facility comfort or home operations.

High-Efficiency Furnaces: Designed to operate at 90–98% efficiency, these units often include advanced features such as variable-speed blowers. While more complex, they can last 20 years or more if you maintain them properly.

Heat Pumps and Hybrid Systems: Heat pumps, though different from traditional furnaces, can extend the life of your gas furnace by reducing strain during milder months.

Knowing your furnace type lets you plan replacements before failures occur, avoiding discomfort and costly emergency repairs.

Key Factors That Affect How Long a Gas Furnace Lasts

Several elements determine whether a gas furnace reaches its full life expectancy or falls short. Understanding these helps you take practical steps to protect your investment.

Installation Quality

Proper installation is critical. A furnace that’s too large or too small for your space will cycle inefficiently. A system that short-cycles wears out faster than one sized correctly for your home’s needs. Poor combustion air flow, incorrect venting, or mismatched ductwork can also stress a furnace over time.

Maintenance Habits

Routine furnace maintenance makes a major difference. Changing filters on time, scheduling annual professional inspections, and cleaning essential parts reduce strain on internal components. Systems without regular service tend to fatigue earlier, increasing the likelihood of failure.

Frequency of Use

How often your furnace runs affects how quickly it wears out. In colder climates or in spaces where heating is used heavily, the furnace runs more frequently and reaches the end of its useful life sooner. Spaces with milder winters put less stress on the system, potentially extending its service life.

Climate and Environment

Harsher winters push furnaces to work harder and longer. Excess dust, humidity, or corrosive conditions like salt air can also increase wear and tear on internal components. Keeping indoor air clean and vents clear helps the furnace last longer.

Quality of Parts

Internal elements like the heat exchanger, blower motor, and ignition system don’t all wear at the same rate. Higher-grade parts typically hold up better over time. Lower-cost units may make initial savings appealing, but can require earlier replacement.

By keeping these factors in mind, you can maximize your furnace's service life and plan for a timely replacement.

Warning Signs Your Gas Furnace Needs Replacement

Even well-maintained furnaces eventually reach a point where repairs may no longer be cost-effective. Recognizing early warning signs helps prevent sudden breakdowns during the coldest days of the year.

Some common indicators include:

Age of the Furnace

Older furnaces experience more frequent mechanical failures and operate with lower performance levels. Monitoring the operational age helps you plan maintenance and budgeting more effectively.

Key Considerations:

Service Life Limitations: Furnaces older than 15–20 years may experience frequent component failures.

Operational Impact: Aging units can struggle to maintain consistent heat, affecting temperature-sensitive areas in offices or production spaces.

Planning Advantage: Scheduling replacement ahead of system failure reduces emergency maintenance costs and protects uptime.

Action Steps:

Keep detailed records of installation and service history.

Evaluate replacement when multiple minor repairs are needed over short periods.

Frequent Repairs

A furnace that requires repeated repairs shows declining reliability. Frequent maintenance can disrupt operations and increase overall costs.

Key Considerations:

Operational Disruptions: Each service call may require temporary shutdowns, affecting workflow and productivity.

Cost Implications: Repair expenses can add up faster than investing in a new unit.

Predictability: Planning replacement improves operational stability and reduces surprise outages.

Action Steps:

Track the frequency and type of repairs.

Compare repair costs with the cost of replacement to inform decision-making.

Rising Energy Consumption

An increase in energy use often points to reduced furnace efficiency. Facilities experiencing higher heating bills should review system performance.

Key Considerations:

Cost Per Unit Impact: Inefficient heating increases operational costs without adding value.

Energy Management: Monitoring energy consumption helps identify aging equipment before failure.

Process Stability: Consistent heat is essential for production areas, server rooms, and offices.

Action Steps:

Review utility bills for abnormal increases.

Conduct an energy audit to identify inefficiencies.

Uneven Heating Across Spaces

Temperature inconsistencies across a facility often indicate the furnace is unable to distribute heat properly. This directly affects comfort and operational outcomes.

Key Considerations:

Work Environment: Uneven temperatures can impact staff performance and comfort.

Equipment Performance: Sensitive machinery may rely on stable ambient temperatures.

Throughput Risk: Inconsistent heat can slow production or affect process quality.

Action Steps:

Inspect ductwork and vents for blockages or leaks.

Consider a professional assessment to determine if the furnace can meet load requirements.

Unusual Noises or Odors

Strange sounds or smells frequently signal mechanical or safety issues. Ignoring these signs increases the risk of system failure or unsafe conditions.

Key Considerations:

Mechanical Health: Rumbling, banging, or squealing sounds indicate worn components.

Safety Risk: Burning odors or gas smells can signal potential hazards.

Maintenance Planning: Addressing issues early prevents emergency repairs and downtime.

Action Steps:

Keep a log of noises or odors and their frequency.

Schedule an immediate inspection when abnormal activity is detected.

Yellow or Flickering Pilot Light

A stable blue flame indicates proper operation in modern gas furnaces. A yellow or flickering flame often signals incomplete combustion or carbon monoxide risks.

Key Considerations:

Safety Concern: Risk of carbon monoxide exposure can impact staff and occupants.

Compliance Risk: Facilities must comply with safety regulations for gas appliances.

Operational Continuity: Unsafe furnaces may require shutdown until resolved.

Action Steps:

Monitor flame color during routine checks.

Engage licensed technicians to inspect and, if necessary, replace the system.

Frequent Cycling or Short-Cycling

Short-cycling occurs when a furnace turns on and off rapidly. This places excess stress on components and reduces overall system performance.

Key Considerations:

Component Wear: Rapid cycling accelerates the deterioration of key parts.

Energy Waste: Frequent start-stop cycles increase utility costs.

Reliability Impact: Reduces confidence in maintaining consistent temperature across the facility.

Action Steps:

Track cycling frequency and patterns.

Schedule a professional assessment to determine if repair or replacement is the better long-term solution.

Each of these indicators alone does not automatically require immediate replacement. However, when multiple issues appear, particularly in a 15+ year-old system, delaying action can create unsafe operating conditions.

Best Time of Year to Replace a Gas Furnace

You might wonder whether there’s an ideal season to install a new furnace. While furnaces can be replaced at any time of year, certain periods offer advantages:

Spring: Reduced System Strain

Spring is ideal because your furnace is not under heavy use. Replacing it now helps:

Minimise Equipment Downtime: The HVAC system is less critical in spring, reducing operational disruption.

Plan Maintenance Efficiently: Technicians have more availability, enabling quicker scheduling.

Control Replacement Costs: Avoid peak-season premiums that arise during heavy heating months.

Summer: Flexible Scheduling and Supplier Access

During summer, scheduling replacement becomes easier, and supply chain issues are easier to manage:

Faster Parts Availability: Manufacturers and suppliers are less busy, reducing component lead times.

Minimal Production Impact: Furnace downtime is less likely to disrupt workflow or facility comfort requirements.

Budget Planning: Timing replacements during low-demand months allows for better financial allocation.

Early Fall: Pre-Season Preparation

Replacing a furnace in early fall ensures the system is fully operational before peak usage:

Prevent Emergency Shutdowns: Avoid unplanned downtime during critical heating periods.

Ensure Consistent Performance: A new system supports stable temperature control for ongoing operations.

Improve Predictable Planning: Allows teams to coordinate maintenance schedules and energy usage.

Planning your replacement around these periods can minimize disruption and allow you to choose the system that best fits your space and budget.

How Quality Comfort Solutions Can Help With Your Gas Furnace Needs?

Quality Comfort Solutions is a trusted HVAC provider in Yonkers and throughout Westchester County, offering expertise in installing, repairing, and maintaining gas furnaces.

Here’s how we can help you:

Expert Furnace Installation and Replacement: Our licensed technicians install new systems with precision, ensuring reliable performance and long-term comfort for your home.

Seasonal Maintenance Services: Regular fall and spring tune-ups keep your furnace running efficiently, reduce the risk of breakdowns, and extend the life of your system.

Prompt and Reliable Repairs: We quickly diagnose and fix issues, from minor repairs to major malfunctions, keeping your home warm when you need it most.

Guidance on System Selection: Our team helps you choose the right furnace type and efficiency level for your home, balancing comfort, energy use, and budget.

24/7 Support for Urgent Needs: Day or night, we are available to address emergencies, ensuring your home stays safe and comfortable.

Partnering with Quality Comfort Solutions ensures a team that prioritizes your comfort, safety, and long-term investment in your heating system.

Conclusion

Gas furnaces are built to provide reliable heating for 15–25 years, depending on the type, usage, and care. Watching for signs like frequent breakdowns, rising energy costs, uneven heating, or strange noises helps you plan for replacement before a cold snap hits.

Scheduling replacement during the best times of the year ensures smoother transitions and minimal disruption to your comfort. Professionals like Quality Comfort Solutions offer expert installation, reliable maintenance, and guidance tailored to your needs.

Contact us for a free estimate to review your facility’s furnace needs and plan for reliable heating performance.

FAQs

1. At what age should I start planning to replace my gas furnace?

Most gas furnaces last 15–20 years. If your unit is over 15 years old, requires frequent repairs, or shows uneven heating, it’s wise to start planning for a replacement to avoid sudden breakdowns and maintain energy efficiency.

2. What are the costs associated with replacing a gas furnace?

Replacement costs vary by furnace type, size, and installation complexity. On average, a standard gas furnace ranges from $3,000 to $6,000, including installation. High-efficiency or larger units can exceed $7,000, so budgeting and comparing local quotes are essential.

3. Are there efficiency differences between old and new gas furnaces?

Yes, modern furnaces are significantly more energy-efficient, often rated 90–98% AFUE, compared to older models at 60–80% AFUE. Upgrading can reduce heating costs, improve comfort, and lower your home’s environmental impact.

4. How do I know if repairing my gas furnace is worth it versus replacing it?

Consider age, repair frequency, and cost. If your furnace is over 15 years old, requires major repairs, or efficiency is low, replacement is often more cost-effective than ongoing repairs. Minor issues in newer units may justify repair instead.

5. What should I consider when choosing a replacement gas furnace?

Look at energy efficiency (AFUE rating), furnace size for your home, installation costs, warranty, and reliability. Choosing a model that matches your home’s heating needs ensures comfort, lower energy bills, and long-term value.