A frozen central air line can be frustrating, especially during hot months when you rely on consistent cooling. Many homeowners and light commercial operators in Westchester County, NY, encounter this problem, but it’s often misunderstood. A freeze-up can drastically reduce cooling speed, increase energy bills, and place strain on your HVAC system, shortening its lifespan.

Recognizing the causes and addressing the issue quickly can help maintain system reliability and reduce operational disruptions. In fact, well-maintained systems usually last 15–20 years, while units that don’t receive regular care may need replacement in as little as 10 years.

In this guide, we’ll explore why your central air line freezes, how to spot the early signs, what to check immediately, and when it’s time to involve a licensed HVAC professional.

Key Takeaways:

A frozen central air line indicates airflow, refrigerant, or mechanical issues that lower cooling performance and strain your HVAC system.

Early signs of freezing include slow cooling, ice on lines, unusual noises, frequent cycling, and excess condensation.

Common causes range from dirty filters, low refrigerant, blocked coils, and airflow issues to faulty thermostats, motors, or system components.

Immediate steps include turning off the AC, running the fan, checking filters and vents, allowing the system to thaw, and seeking professional inspection for recurring problems.

What Does It Mean When Your Central Air Line Freezes?

When your central air line develops ice or frost, it indicates that something is preventing your system from exchanging heat or airflow properly. This freezing typically happens on the suction line, the larger refrigerant pipe that returns cooled refrigerant to the compressor, but it can affect the entire cooling loop.

A frozen line prevents your system from removing heat effectively from your home, slowing cooling and putting extra wear on key components.

Early Warning Signs Your AC Line Is Freezing

Identifying a freezing AC line early can save time, money, and stress. Look for these signs in your system:

Reduced cooling performance: Your rooms take longer to reach the desired temperature.

Frost or ice on refrigerant lines: Ice may appear around indoor coils or exposed piping.

Unusual system noises: Listen for gurgling, hissing, or bubbling sounds from the AC unit.

Frequent cycling: The system may turn on and off more often than usual, indicating strain.

Condensation issues: Watch for excess water or dripping near the indoor unit.

Noticing these signs early helps you act quickly or contact a licensed HVAC technician to prevent further damage.

The Most Common Reasons Your Central Air Line Freezes and Stops Cooling Fast

Several factors can cause your AC line to freeze. Identifying the root cause helps prevent repeated freeze-ups and keeps your cooling system reliable.

Below is a breakdown of common causes:

Dirty or Clogged Air Filters

Air filters trap dust and debris, protecting the system and maintaining airflow. When filters are clogged:

Airflow decreases, preventing warm air from reaching the evaporator coil.

The coil temperature drops below freezing, causing ice buildup.

System efficiency declines, and run times increase, raising energy costs.

Tip: Replace or clean filters every 1–3 months to maintain airflow and prevent freeze-ups.

Low Refrigerant Levels from Leaks

Refrigerant absorbs heat from your home and releases it outside. Low refrigerant levels usually result from leaks, causing:

Reduced heat absorption at the evaporator coil.

Supercooled refrigerant that freezes the line.

Longer systems run cycles, stressing the compressor.

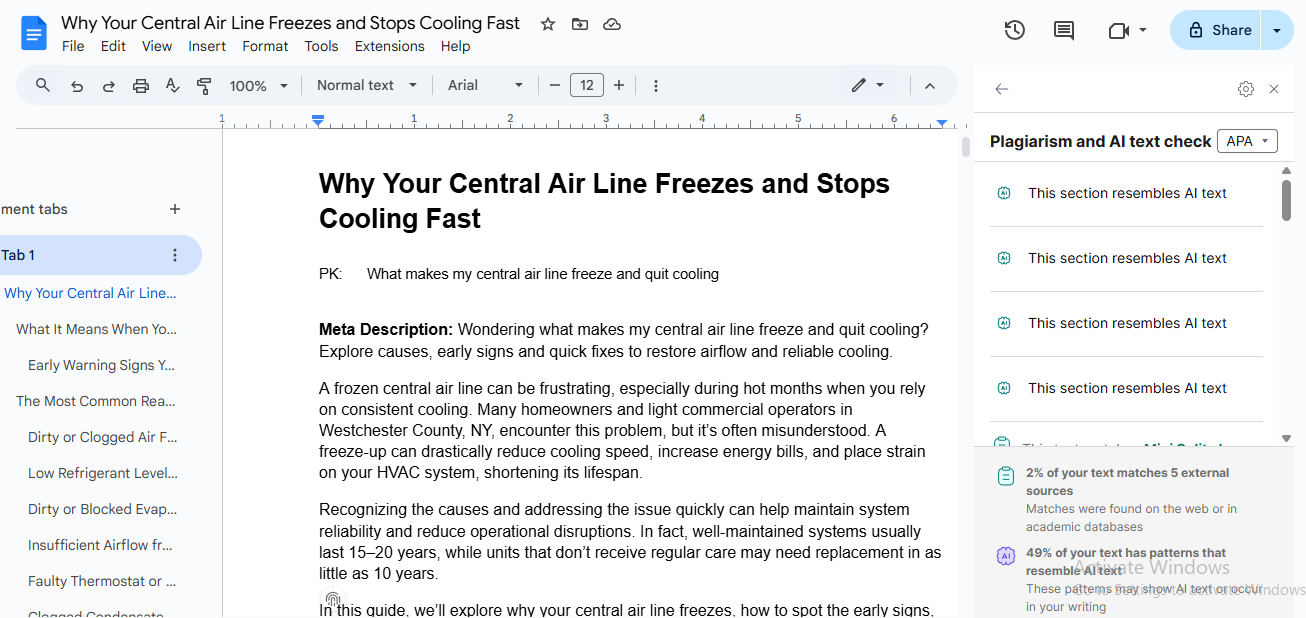

A licensed technician should identify leaks and recharge the refrigerant safely. Improper handling can damage the system or violate regulations.

Dirty or Blocked Evaporator/Condenser Coils

Evaporator coils inside your home and condenser coils outside are vital for heat exchange. Dirt buildup reduces heat absorption and airflow, which can lower coil temperatures enough to cause freezing.

Effects on performance:

Slower temperature regulation

Greater energy usage

Potential system wear

Maintenance check: Clean coils at least once a year during routine tune-ups.

Insufficient Airflow from Closed or Blocked Vents

Closing vents or blocking airflow in certain rooms can disrupt the balance of the system. Without adequate airflow over the evaporator coil, the refrigerant temperature can drop too low, forming ice.

Operational impact:

Uneven cooling across rooms

Increased system pressure

Higher energy costs

Quick fix: Make sure vents are open and unobstructed.

Faulty Thermostat or Incorrect Settings

If the thermostat malfunctions or is set improperly, the system may run longer than necessary, causing low refrigerant temperatures and frozen lines.

Impact:

Overshooting cooling cycles

System strain

Unnecessary energy usage

Solution: Calibrate thermostats correctly, replace batteries, or upgrade to a compatible model if needed.

Condensate Drain Line

The condensate drain removes moisture from the system. If blocked, water accumulates around the coil, which causes ice formation and water damage.

Practical outcomes:

Reduced cooling efficiency

Potential overflow and leakage

System downtime

Maintenance tip: Regular inspection of the drain line keeps water moving and prevents freeze-ups.

Broken Blower Fan or Motor

The blower fan circulates air over the coils. If it fails or slows down, the evaporator coil can become too cold, freezing the lines.

Operational effects:

Poor airflow and uneven cooling

Increased compressor load

Higher energy bills

Prompt professional repair ensures consistent airflow and system reliability.

Low Outdoor Temperatures

Air conditioners are designed for warmer conditions. Running the system in unusually cold weather can lower refrigerant temperature, causing freezing.

Operational considerations:

Reduced system performance

Risk of mechanical damage

Temporary inefficiency

Recommended action: Shut off cooling during cold snaps or use heat pump defrost cycles to prevent this issue.

Oversized AC Unit or Faulty Expansion Valve

An oversized system or a malfunctioning expansion valve can cause refrigerant to flow incorrectly. Excess cooling without adequate load can result in ice on the lines.

Impact on operations:

Short cycling

Increased wear on components

Uneven temperature control

Review system sizing and maintain the expansion valve to correct these mechanical problems.

Other Mechanical or System Issues (Control Boards, Duct Problems)

Electrical or ductwork problems can also lead to frozen lines. For instance, control board malfunctions may mismanage airflow or refrigerant, and leaks in ductwork can reduce pressure and airflow over the coils.

Consequences:

Inconsistent cooling

Higher energy usage

Potential for long-term damage

A full professional inspection is often required to diagnose these complex issues.

What to Do Immediately If Your Central Air Line Freezes?

Immediate actions can help limit damage until professional service is available. The steps below focus on what you can safely check without risking equipment damage.

Step | What to Do |

Turn off the AC system | Switch the thermostat to OFF as soon as you notice freezing. |

Set the fan to ON | Change the thermostat fan setting from AUTO to ON. |

Replace or clean the air filter | Check the filter; replace it if clogged. |

Check supply and return vents | Make sure all vents are open and not blocked by furniture or coverings. |

Allow the system to fully thaw | Wait several hours for all ice to melt before restarting. |

Look for water or moisture around the unit | Check the indoor unit for dripping or pooled water. |

Stop using the AC if freezing returns | Do not run the system after repeated freeze-ups. |

Avoid DIY refrigerant or internal repairs | Do not attempt to adjust refrigerant or internal components yourself. |

If the line freezes again after these steps, the issue is likely internal and needs professional diagnosis to prevent recurring cooling loss and damage.

How Quality Comfort Solutions Helps Restore Cooling and Prevent Freezing?

Quality Comfort Solutions provides licensed, reliable HVAC services across Yonkers and Westchester County. Our approach focuses on diagnosing root causes and implementing long-term solutions.

Here’s how we can support you:

Accurate system diagnosis: Technicians check airflow, refrigerant balance, coils, and controls to pinpoint what caused the freeze, not just the visible ice.

Airflow and component checks: Blower operation, filters, vents, and duct connections are reviewed to restore stable airflow across the evaporator coil.

Refrigerant and leak assessment: Refrigerant levels and potential leaks are inspected to correct pressure issues that lead to ice formation.

Targeted repairs, not guesswork: Faulty parts such as thermostats, motors, or valves are addressed only where needed to reduce unnecessary work.

Preventive maintenance support: Seasonal tune-ups help reduce repeat freeze events, support steady cooling, and limit unexpected system downtime.

Local, licensed service coverage: Based in Yonkers and serving Westchester County, the team responds quickly with solutions suited to local climate conditions.

Working with a trusted local team ensures your AC operates efficiently, reduces downtime, and prolongs system life.

Conclusion

A frozen central air line signals airflow, refrigerant, or mechanical issues that require attention. Ignoring these early signs can reduce cooling speed, increase energy costs, and strain your system. Common causes include dirty filters, low refrigerant, blocked coils, airflow issues, and faulty components.

Preventive measures such as regular maintenance, proper thermostat settings, and professional inspections help avoid freeze-ups and ensure reliable, cost-effective cooling. For homeowners and light commercial operators in Yonkers and Westchester County, working with licensed experts like Quality Comfort Solutions provides both peace of mind and reliable system performance.

Contact us for a free estimate and get expert help restoring fast, reliable cooling while preventing future AC line freeze-ups.

FAQs

Can a malfunctioning thermostat make my central air line freeze?

Yes, a faulty thermostat can cause the AC to run continuously or fail to cycle properly. This prevents the system from regulating temperature, leading to excessive cooling and ice forming on the central air line.

How does high humidity contribute to frozen evaporator coils?

High humidity increases moisture in the air. When the AC struggles to remove this excess moisture, condensation on the evaporator coils can freeze. Over time, this ice buildup restricts airflow and reduces cooling efficiency.

Why does my AC freeze up at night but not during the day?

Nighttime freezing often occurs because cooler outdoor temperatures reduce the AC’s load, causing it to run less efficiently. Lower temperatures and slower airflow can allow evaporator coils to drop below freezing, leading to ice formation.

Can restricted airflow from blocked vents cause line freezing?

Yes, blocked vents or dirty filters reduce airflow over the evaporator coils. Insufficient airflow prevents proper heat exchange, causing the coils to get too cold and ice to form on the central air line.

How can low refrigerant levels lead to a frozen AC line?

Low refrigerant reduces pressure in the system, lowering the evaporator coil temperature. When coils get too cold, moisture freezes on the line. Persistent low refrigerant can cause repeated freezing and damage to the AC system.