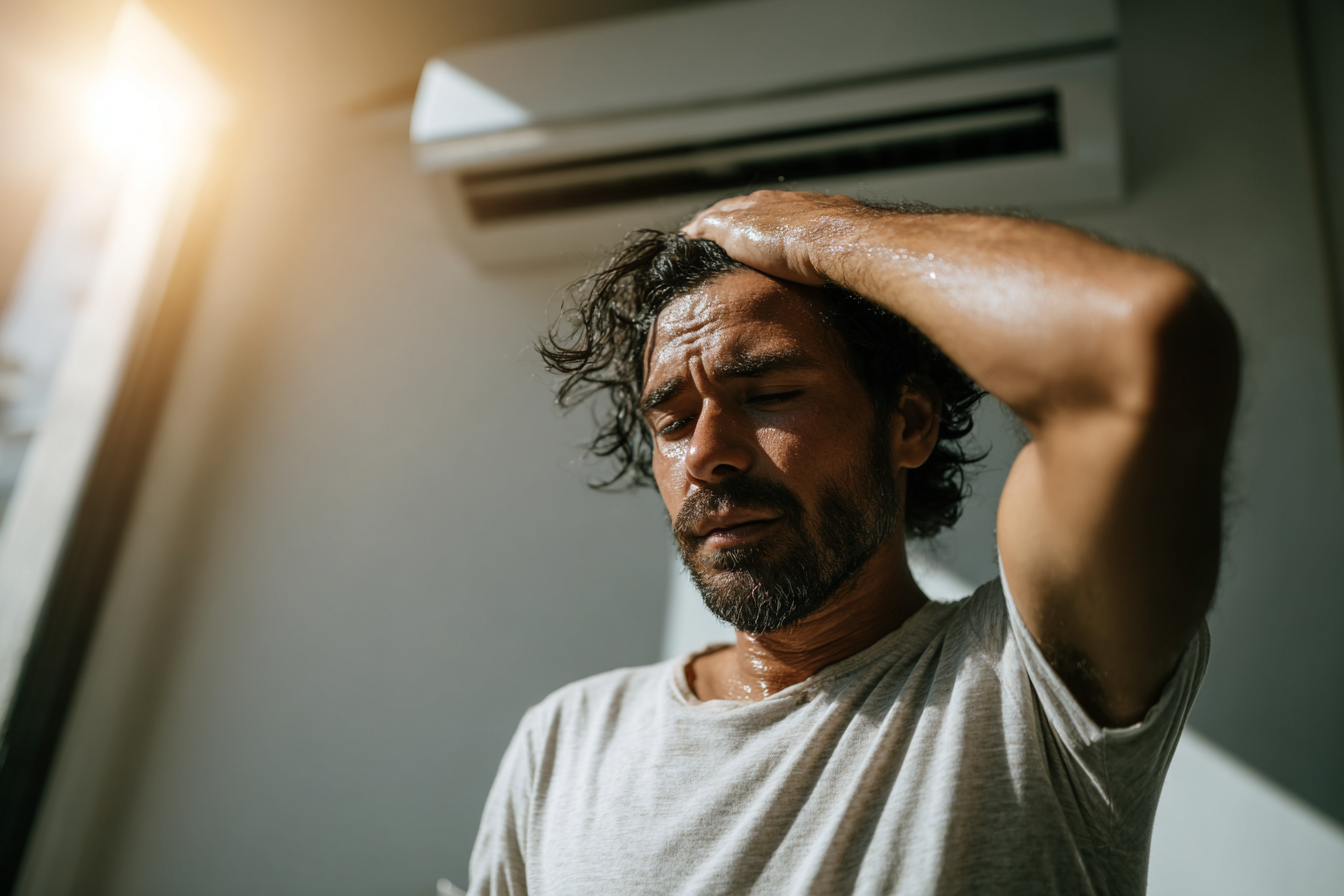

Your air conditioner can be running, but if the compressor is struggling, your home will feel the heat. It’s the “heart” of the cooling system, and when it fails, comfort, efficiency, and safety start slipping fast.

Only about 30% of American homeowners schedule regular HVAC maintenance, leaving most compressors to work through hidden problems until they become expensive emergencies. Because when an AC loses its compressor, it’s not just cool air you lose. It’s money, peace of mind, and time you don’t have in the middle of summer.

This guide explains how to recognize compressor problems early, what the main causes are, and how expert diagnostics prevent full system failures, so you’re not left replacing something that could have been repaired.

Need to know

The AC compressor is essential for cooling your home; even a minor issue can affect performance and efficiency.

Only a small percentage of homeowners perform routine HVAC maintenance, leading to preventable compressor failures.

Early symptoms like warm air, weak airflow, and rising energy bills should never be ignored.

Low refrigerant levels, electrical faults, and airflow restrictions are the most common causes of failure.

Professional diagnostics identify the root cause and help prevent unnecessary replacements.

What Is an AC Compressor?

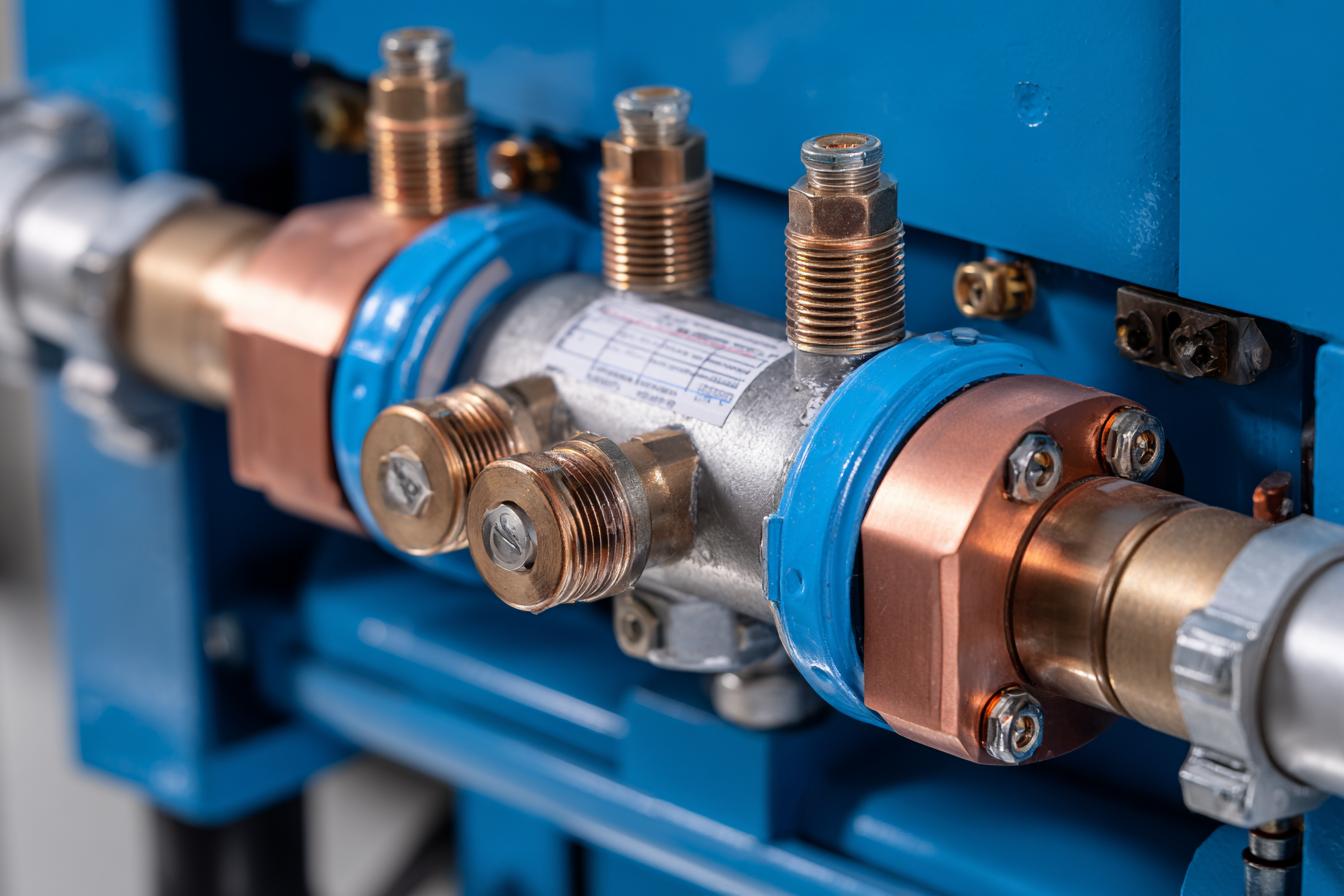

Inside every air conditioning system, the compressor is the component responsible for pressurizing refrigerant and pushing it through the system. It takes low-pressure refrigerant gas from the evaporator coil and compresses it into a high-pressure, high-temperature state.

That compressed refrigerant then travels through the condenser coil, releasing heat to the outside before circulating back indoors to absorb more heat.

Why Is the AC Compressor Important?

The compressor is essential to the cooling process. Without it, the refrigerant can’t circulate, and heat can’t be transferred out of your home. A properly functioning compressor ensures:

Efficient Cooling: Maintains proper refrigerant flow, so your home reaches the set temperature faster.

Energy Savings: Reduces strain on the system, helping you avoid increased electricity usage.

Longer System Lifespan: Prevents additional wear on other critical components, such as the condenser fan and evaporator coil.

Consistent Indoor Comfort: Keeps temperature and humidity levels stable throughout the home.

Because the compressor affects every part of the cooling cycle, even a minor issue can create noticeable changes in comfort and system performance.

Common Signs Your AC Compressor Is Failing

A compressor rarely stops working without warning. It usually shows early symptoms that something is wrong with refrigerant flow, electrical components, or internal pressure. Here are the key signs to watch for, and why they matter:

1. Warm Air Instead of Cool Air

The AC is running, but the indoor air feels warm or only slightly cool.

What it means: The compressor can’t raise the refrigerant pressure, which prevents heat from being carried outside.

Impact: The system works harder for less cooling, leading to overheating, increased wear, and potential failure in extreme heat.

2. Weak or Reduced Airflow

Air coming from the vents feels weaker than usual, even at high fan speed.

What it means: The loss of refrigerant pressure prevents proper heat transfer, so air doesn’t cool efficiently.

Impact: Rooms take longer to reach the set temperature, causing higher energy use and strain on the compressor.

3. Frequent System Shutdowns or Hard Starts

The AC struggles to start, or the outdoor unit shuts off unexpectedly.

What it means: This often indicates failing electrical components, such as capacitors or a compressor that’s drawing too much power.

Impact: Overheating risks increase, and repeated breaker trips signal that severe failure is imminent.

4. Loud or Unusual Noises from the Outdoor Unit

Buzzing, rattling, or grinding sounds occur when the AC is running.

What it means: Electrical buzzing indicates bad contactors or wiring, while grinding or clunking means internal mechanical damage.

Impact: Continued operation can damage other parts inside the compressor, often leading to irreversible failure.

5. Ice Buildup on Coils or Refrigerant Lines

Frost appears on the outdoor unit or copper tubing.

What it means: Low refrigerant pressure or poor airflow prevents proper heat exchange.

Impact: Ice further restricts refrigerant flow, forcing the compressor into continuous, high-stress operation.

6. Rising Energy Bills Without Increased Use

Cooling costs jump suddenly compared to previous months.

What it means: The compressor needs more time and electricity to achieve standard cooling because its efficiency has dropped.

Impact: If ignored, this can lead to premature burnout and expensive repairs, or even full AC replacement.

Even one or two of these symptoms can signal a developing issue. When several appear together, the compressor is already under excessive strain.

Need expert diagnostics and compressor repair? Contact Quality Comfort Solutions today to get your AC running like new!

What Causes Compressor Problems?

Compressor issues usually develop slowly due to stress, lack of maintenance, or component failures elsewhere in the system. The compressor is built to handle heavy workloads, but when other parts aren’t functioning correctly, the compressor is the one that pays the price.

Below are the most common causes of compressor failure and how they impact your AC:

Refrigerant Leaks or Low Levels: When refrigerant escapes, the compressor works harder to pressurize the remaining refrigerant. This leads to overheating, internal damage, and eventual burnout if not corrected.

(Refrigerant loss is one of the leading causes of compressor failure.)

Electrical Failures: Damaged wiring, failing capacitors, or loose electrical connections prevent the compressor from receiving stable power. This causes hard starting, frequent shutdowns, and irreversible motor damage over time.

Restricted Airflow Around the Outdoor Unit: Debris, dirt buildup, or blocked coils trap heat that should be released outside. When excess heat stays inside the system, the compressor overheats and shuts down to protect itself until it can’t anymore.

Dirty or Clogged Components (Coils, Filters, or Lines): Contamination reduces heat transfer efficiency, forcing the compressor to work longer. Long-term strain causes accelerated wear and higher cooling costs.

Incorrect Refrigerant Charge: Too little or too much refrigerant affects pressure balance. This leads to liquid refrigerant entering the compressor, a mechanical failure known as slugging, which can destroy internal parts.

System Age and Natural Wear: Older compressors lose efficiency and lubrication. After a decade or more of service, internal components become more prone to overheating, noise, and frequent repairs.

Contaminants or Moisture in Refrigerant Lines: Dirt or water entering the system can corrode metal surfaces and damage valves. Left unresolved, contaminants cause complete compressor seizure.

Improper Installation or Sizing: A mismatched system or poor setup causes continuous operational stress. Compressors installed incorrectly are far more likely to fail prematurely.

Most compressor failures start small, but once the internal components are damaged, repairs become expensive or impossible.

How Technicians Diagnose Compressor Issues?

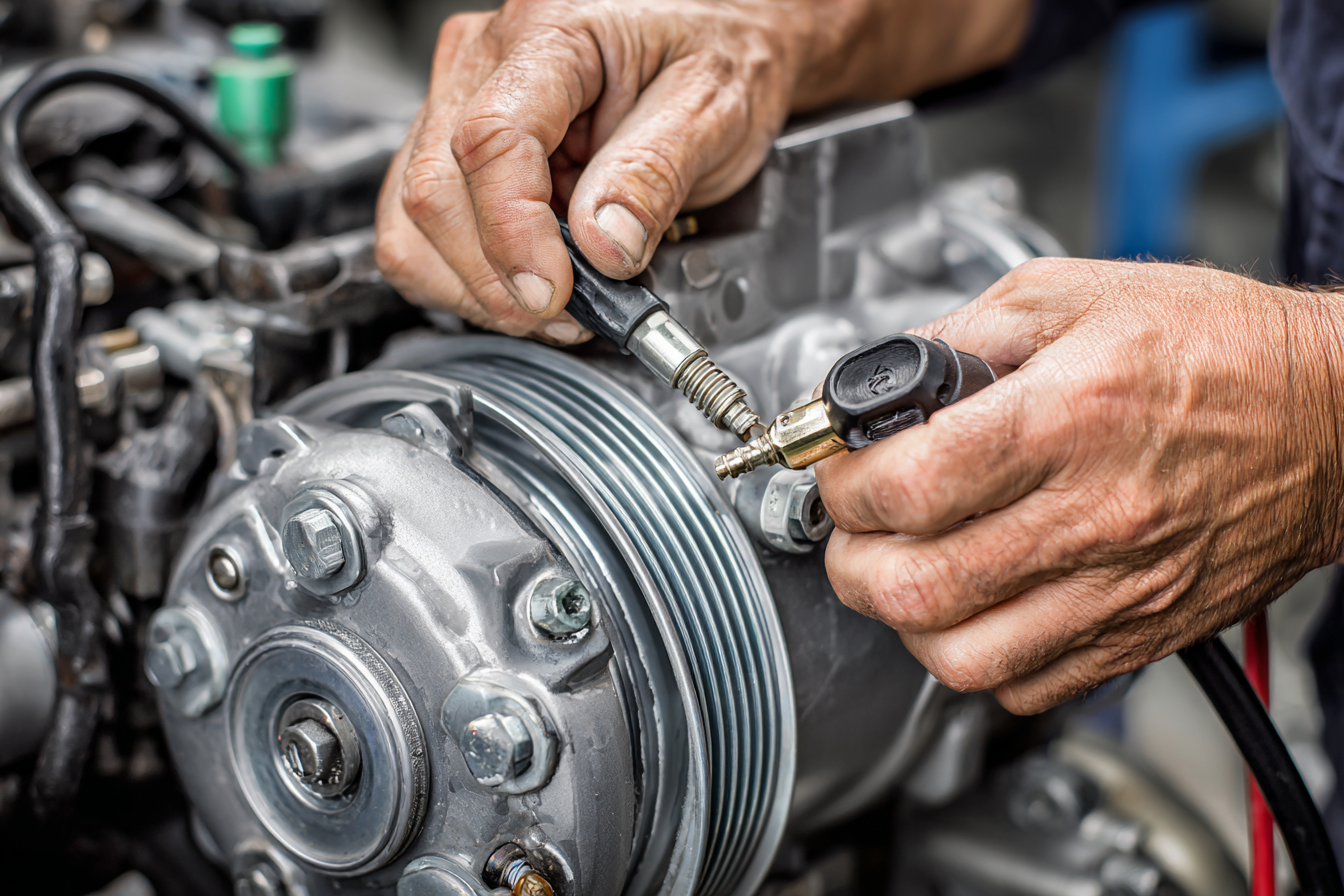

Because the compressor is connected to nearly every part of the cooling system, proper diagnosis requires a step-by-step approach. A licensed HVAC technician doesn’t just look at the outdoor unit; they evaluate the entire refrigerant and electrical network to find the true cause of the problem.

Here’s what typically happens during a compressor diagnostic:

1. System Performance Evaluation

Technicians start by checking temperature differences between the supply and return air.

What it reveals: Whether the AC is moving heat properly or struggling to cool effectively.

2. Refrigerant Pressure Testing

Pressure gauges are connected to measure refrigerant flow throughout the system.

What it reveals: Low charge, leaks, or pressure imbalances that strain the compressor.

3. Electrical Component Inspection

Capacitors, contactors, relays, and wiring are tested for voltage and continuity.

What it reveals: Startup failures, hard starting, or electrical overheating risks.

4. Visual and Physical Inspection of Outdoor Components

Technicians check the condenser coil condition and ensure air can move freely around the unit.

What it reveals: Heat buildup caused by dirt, debris, or blocked airflow.

5. Vibration, Noise, and Motor Condition Check

Listening and testing tools help pinpoint mechanical wear or internal damage.

What it reveals: Whether the compressor’s motor or valves are beginning to fail.

6. Thermal Protection and Overload Testing

Sensors and safety features are checked for signs of overheating.

What it reveals: Whether the compressor is shutting down under stress to prevent burnout.

7. Oil and Contaminant Check (When Needed)

Some systems allow technicians to inspect oil for metal particles or moisture.

What it reveals: Internal wear, a sign that repairs may no longer be viable.

By completing all of these steps, technicians can determine:

Can the compressor be repaired affordably?

Is another component the real cause of the issue?

Will repairing it simply delay an inevitable replacement?

Accurate diagnostics save homeowners from paying for unnecessary parts or replacing a healthy system because of a misdiagnosed problem.

Repair vs. Replacement: What Homeowners Should Know

A failing compressor doesn’t always mean you need a new AC system. In many cases, a specific part can be replaced or repaired to restore proper operation. However, there are times when putting more money into an aging compressor delays a much larger expense.

The right decision depends on cost, system age, refrigerant type, and the AC's overall condition.

Here’s a simple breakdown to guide expectations:

Situation | What It Means | Best Option | Why |

AC is under 10 years old and in good condition | The unit still has years of service life left | Repair | Restores efficiency without unnecessary investment |

Electrical parts, not internal damage cause the issue | The problem is likely small and isolated | Repair | Often, a quick, affordable fix |

Refrigerant leak can be located and sealed | The compressor isn’t the root cause | Repair | Protects the system from future strain |

AC is 10–15+ years old | Efficiency and reliability decline with age | Replace | Avoids recurring repair costs |

Uses R-22 refrigerant | Outdated and expensive to recharge | Replace | Improves energy efficiency and long-term savings |

The compressor has severe internal damage | Repair would be costly with uncertain results | Replace | Prevents paying twice for the same issue |

Multiple repairs in recent years | Symptoms may return soon | Replace | A newer system eliminates ongoing issues |

The right choice protects both your comfort and your wallet, without paying twice for the same problem later.

Don’t wait on a failing AC — contact Quality Comfort Solutions now for professional compressor repair and fast relief!

How to Prevent Compressor Damage?

Most compressor failures are avoidable with the proper system care. Preventive maintenance reduces strain on the compressor, keeps airflow unobstructed, and helps detect minor issues before they turn into expensive breakdowns.

Here are simple steps homeowners can take to extend the life of their AC compressor:

Schedule Routine Professional Maintenance: Seasonal checkups (especially before summer) help catch refrigerant leaks, electrical issues, and airflow restrictions early, keeping the compressor running efficiently.

Replace or Clean Air Filters Regularly: Dirty filters restrict airflow, causing the system to run longer and the compressor to work harder than necessary. A clean filter protects efficiency and comfort.

Keep the Outdoor Unit Clear of Debris: Leaves, dirt, and objects near the condenser trap heat. Maintain at least 2–3 feet of clearance around the unit to allow proper heat release.

Check for Unusual Noises or Performance Changes: Don’t ignore early signs like warm air or increased run time. Addressing problems quickly prevents overheating and internal damage.

Ensure Proper Thermostat Use: Setting the temperature extremely low won’t cool the home faster; it only forces the compressor to run longer, increasing wear and tear.

Avoid Blocking Vents and Registers: Closed or obstructed vents reduce airflow, causing system imbalance and strain on the compressor.

Make Sure the System Has Proper Refrigerant Levels: If cooling declines, don’t continually force the AC to run harder. Low refrigerant is a major cause of compressor burnout, and must be corrected by a professional.

Use Shade When Possible: Providing shade to the outdoor unit can reduce external heat load, helping the compressor operate under less stress during peak temperatures.

Even small maintenance habits greatly reduce the risk of unexpected failure, keeping your AC reliable through the hottest months.

How Quality Comfort Solutions Protects Your Home Comfort

Every home’s cooling needs are different. Quality Comfort Solutions ensures your HVAC system is serviced with precision, maintained for efficiency, and protected for long-term performance.

Our strengths include:

Diagnostic-Driven Service: We evaluate refrigerant levels, airflow balance, and electrical performance to pinpoint the exact issue, so repairs fix the cause, not just the symptom.

Tailored System Solutions: Whether you have central AC, a heat pump, or a ductless unit, we match every recommendation to your home’s unique cooling demands and system design.

Efficiency & Reliability Focused: Optimized equipment operation reduces energy consumption, prevents unexpected breakdowns, and keeps comfort consistent through the hottest days.

Trusted Local Expertise: Serving Yonkers and Westchester County, we provide workmanship backed by industry standards, ensuring safe operation, code compliance, and dependable cooling.

If you’re dealing with warm air, hard starts, or rising utility bills, it may be more than a simple AC issue; your compressor could be under strain. Innovative diagnostics today protect you from expensive failures tomorrow.

Final Thoughts

The AC compressor is one of the hardest-working components in your cooling system, and one of the most expensive to replace. By recognizing early warning signs, keeping up with regular maintenance, and addressing performance changes quickly, you can protect your system from unnecessary failures and costly downtime.

Need help with AC Compressor issues? If your system is getting louder, cooling less, or driving up your energy bills, schedule a diagnostic with Quality Comfort Solutions today. We’ll identify the problem and restore comfort quickly. Call now or schedule an inspection online. Stay ahead of AC problems, and stay comfortable all season long.

Frequently Asked Questions (FAQs)

1. How long does AC compressor repair usually take?

Most repairs can be completed within a few hours, depending on the part that failed and whether replacement components are readily available. Diagnostics are typically done during the same visit.

2. Can a compressor be repaired, or does it always need replacement?

Many issues, primarily electrical or refrigerant-related ones, can be repaired without replacing the entire compressor. Replacement is only recommended when internal mechanical damage is severe.

3. What causes a compressor to fail prematurely?

Low refrigerant, blocked airflow, overheating, and electrical faults are common reasons. Regular maintenance helps identify these early and reduces strain on the compressor.

4. Is it safe to run my AC if the compressor is having problems?

No, continuing to run a struggling compressor can lead to complete motor failure or damage to other system parts, resulting in higher repair costs later.

5. How do I know if repair or replacement makes more sense?

A technician will evaluate the system’s age, refrigerant type, efficiency, and repair cost. Generally, if the unit is older than 10–12 years and the repair is expensive, replacement may be the smarter long-term choice.